(518)6056897

Shop by Category

Polymer Film Production Trial Service

We have multiple polymer film production machines for daily rent trial to customers to develop specialty film process and formulations under NDA:

1. Wet-solution based film casting using slot die (500 mm wide) or reverse comma coating (250 mm wide). Drying oven long from 2 m to 5 m. Polymer solution with appropriate viscosity can be cast on Mylar release carrier and solvents are vaporized when passing a long drying oven. Typical solvents include water, acetone, methyl ethyl ketone, MIBK, etc.

2. Sheet Melt Extrusion: a 1.24" diameter single screw extruder (up to 300 C), a 12" adjustable flex-lip die (facing down), and a horizental three-roll sheet stack (three polished rollers). Can be used to produce polymer film and sheet from 100 um to 2000 um for formulation development

3. Polymer Film Extrusion: a 2.5" dismeter single screw extruder (up to 300 C) with melt pump, manual screen exchanger, and a vacuum feeding system. Flex-lip die is 700 mm wide facing down, two casting rollers. With inline X-Ray thickness scanner (Scantech).

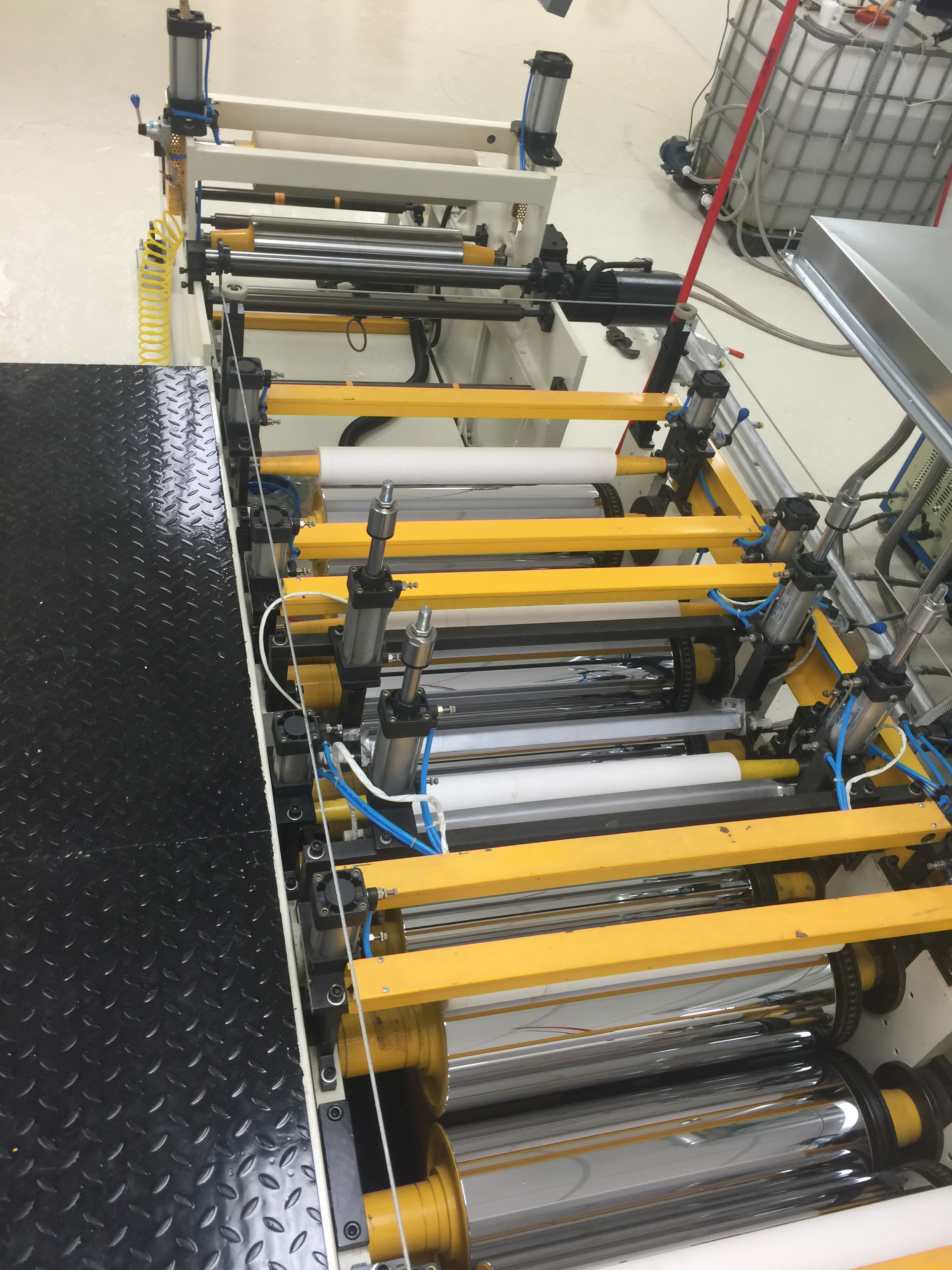

4. Mono-axial (uni-axial) polymer film orientation MDO machine A: 11 rollers with width of 650 mm wide, 9 motors can be individually controlled speed, oil heaters up to 200 C. Line speed up to 5 m/min before stretching.

5. Mono-axial (uniaxial) polymer orientation MDO machine B: 6 rollers with width up to 1000 mm, speed and temperature of each can be individually controlled.

6. A 1000 mm wide slitter/rewinder.

7. Corona Treater (two surfaces) roll to roll.

8. Various polymer film characterization tool: DMA (modulus), Instron Tensile Test, DSC, FTIR, polarized optical microscope, thermal shrinkage, optical UV-VIS transparency, high voltage and dielectric (ASTM D149, D150, D257, D3755, etc)

Short lead time and flexible schedule at affordable cost.

Plastic film processing machines are also available for sale.

Machines located in Philipsburg, PA 16866.

For more details, please email us sale@polyk-lab.com.