Product Description

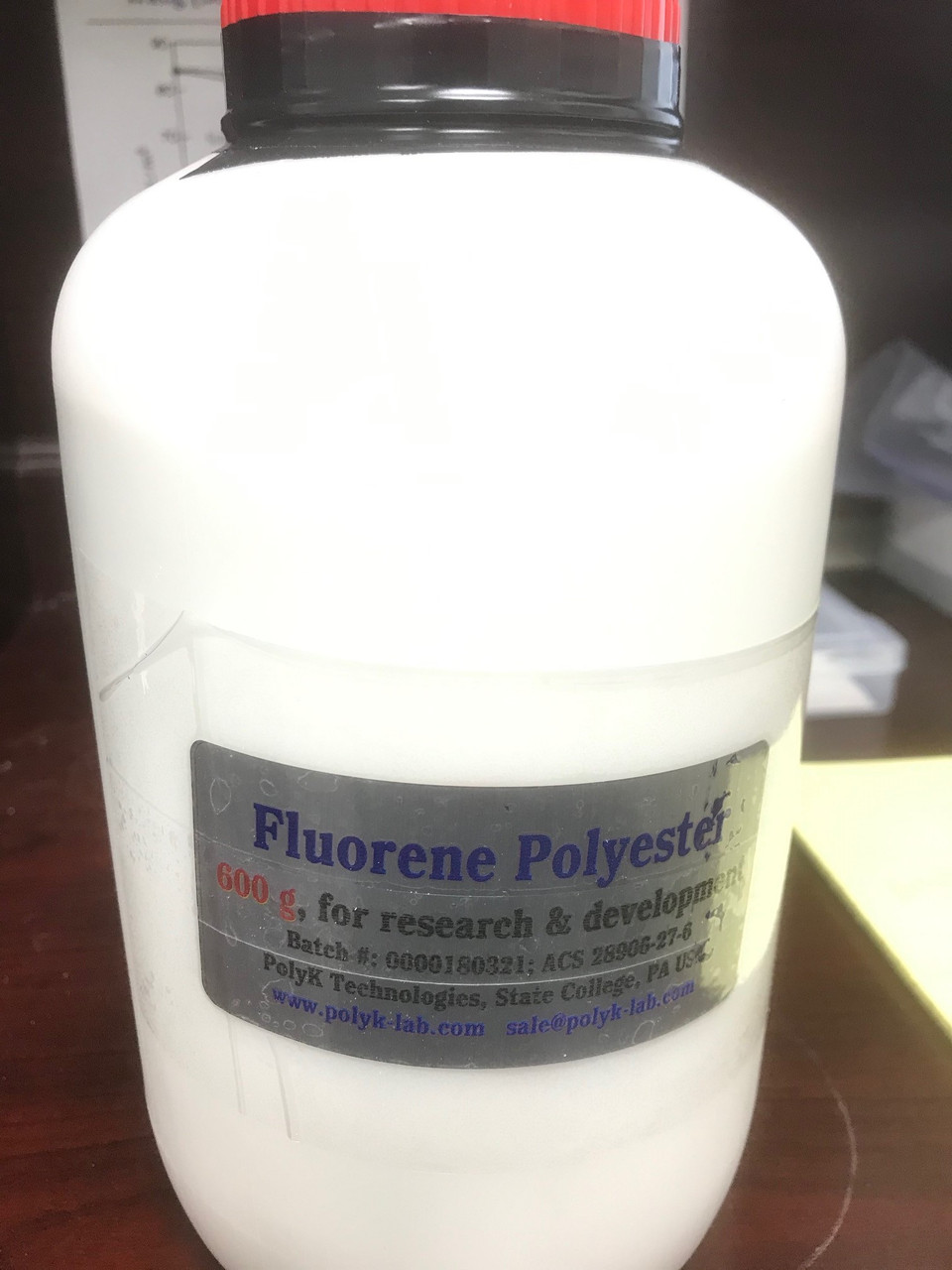

Fluorene Polyester Resin, High Temperature. High Molecular Weight (Intrinsic Viscosity) grade for thin film coating.

Sell in different package size.

Fluorene polyester (FPE) is an amorphous polymer with glass transition temperature above 330 deg C and it can be used as high temperature dielectric materials.

Morphology: Amorphous

Glass Transition: 330 deg C

Molecular Formula: [C33H21O4]n

CAS Number: 28906-27-6

Applications:

- Filtration and seperation membrances

- High temperature capacitors (>200 C ambient):

Evaluation of Fluorene Polyester Film Capacitors https://www.researchgate.net/publication/265284090_Evaluation_of_Fluorene_Polyester_Film_Capacitors

Next generation electrical power systems are being packaged into more compact, power dense architectures as means to improve the performance of electrically-driven technologies. This trend has increased the demand for efficient high voltage power devices that are operable under austere conditions. The capacitive component is commonly identified as a limiting technology with respect to operational use temperature and/or self-heating. Recent industrial processing and metallization of fluorene polyester (FPE) films (T g ~ 330°C) has enabled the manufacturing of wound capacitors that are more temperature tolerant. While a high T g polymer film capacitor is expected to have thermally stable electronic properties, the performance will also be dependent on the architecture and packaging. A modeling and simulation capability is utilized herein to investigate the device architecture-electrical performance relationships for packaged and unpackaged FPE film capacitors. Initially, a mathematical model was developed for both equivalent capacitor circuit analysis and device architecture field analysis, which were used to identify factors that affect device properties. Additionally, finite element analysis of selected device architectures was accomplished to compare magnetic fields and thermal profiles predicted. The electrical properties of packaged and unpackaged FPE devices were then evaluated under stressed conditions, to include cycling from ambient to 200 °C.