Product Description

This listing is for a dual head system (two sputtering targets).

Emitech (Quorum) K557X-D Magnetron Sputter Coater with Turbo Pump, with all parts and Pfeiffer Duo 2.5 vacuum pump, with one new Gold target ($600 value, 50 mm wide, 60 um thick), one 3 mm thick silver target, even with an Argon tubing. With manual and three months warranty. You only need to prepare high purity Argon and electricity [220 Vac single phase] to use the system.

The K575X System employs a magnetron target assembly, which enhances the efficiency of the process using low voltages and giving a fine-grain, cool sputtering.

K575X features a rotating sample table which ensures even depositions. This method allows standard targets to be utilized, and avoids the necessity of special large profile targets.

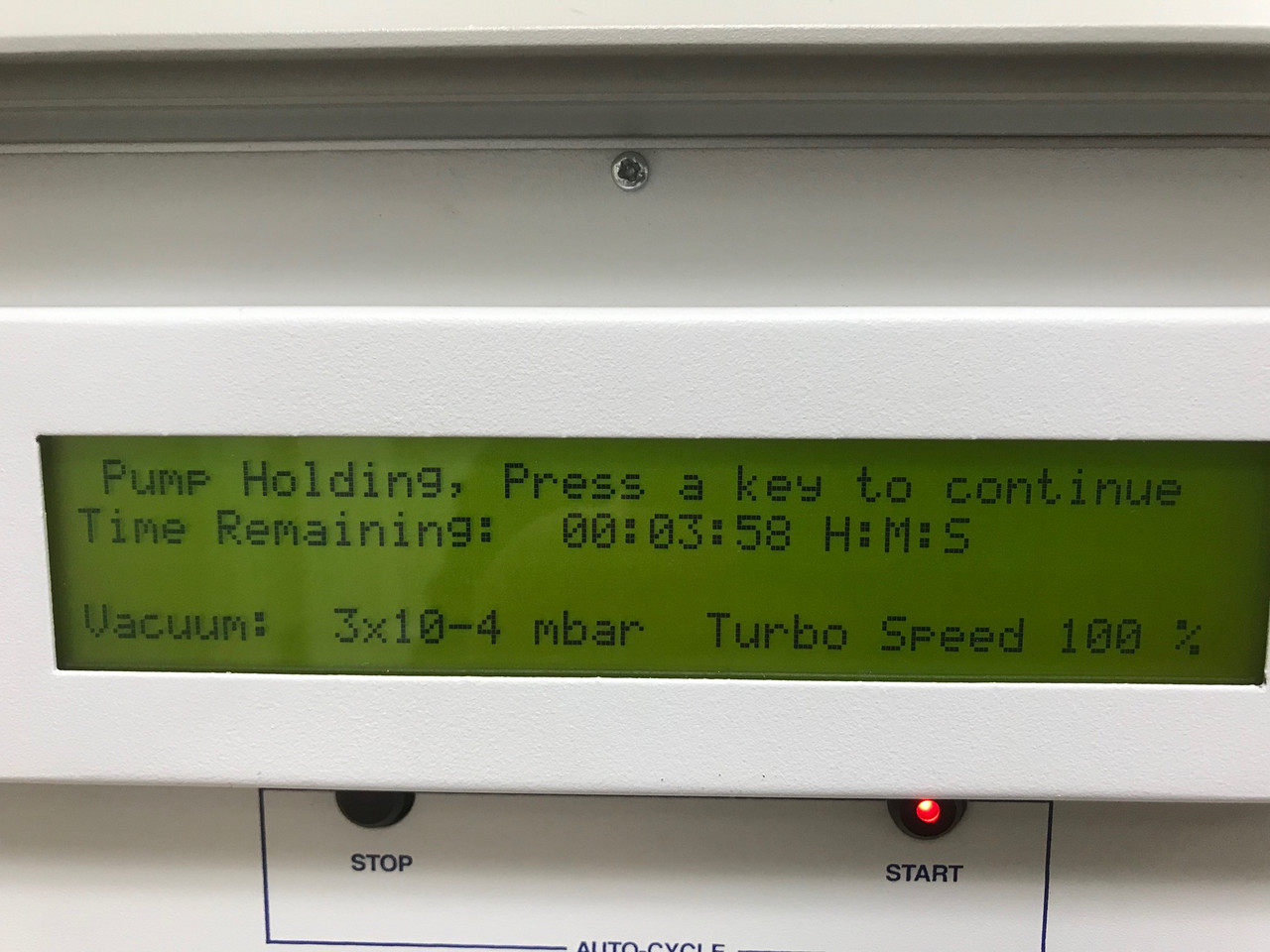

It features a turbo molecular pump backed by a rotary vacuum pump. The Instrument is fitted with a 57mm diameter quick-change target giving optimum consumable cost performance. Alternative target materials are available.

The integrated Instrument panel and plug-in electronics maximize 'up-time' and, with user-friendly designs, ensures satisfactory multi-user discipline.

The sputtering parameters can be pre-set, including the gas bleed needle valve, which has electromagnetic valve back-up.

The independent vacuum pump is controlled by the Instrument throughout the fully automatic coating cycle.

It can be used to sputter coat targets such as Gold, and also targets that may need pre-cleaning for the removal of oxide layers, such as Chromium.

A shutter assembly is fitted as standard, which allows a sputter cleaning and the sputter coating cycle to be carried out while maintaining the vacuum.

The system can also be fitted with a film thickness monitor (FTM) as an "optional extra" for certain applications.

The system can also be fitted with a vacuum shutdown option allowing the instrument to be pumped down and switched off, with the chamber left under vacuum.

Features

- Peltier cooled sputter head

- Fine coating (order of 0.5nm Cr Grain Size)

- Special Rotating Stage with Full Tilt Facility fitted as standard

- Thin Film Deposition (typically 5nm)

- 165mm Diameter Chamber

- Dual Sputter Head available as an option

- Can be integrated with Film Thickness Monitor

Benefits

- Allows sputtering of fine grain oxidizing metals such as Cr or Ir

- Easy to operate

- No cooling water required

- Ultra high resolution reproducible coatings

- Fully adaptable to a wide range of specimens

- Repeatable film thickness depositions

- Easy loading and unloading of samples

- Allows sequential coatings to be made without breaking vacuum

- Can pre-set deposition thickness