Product Description

Overstock from previous research project.

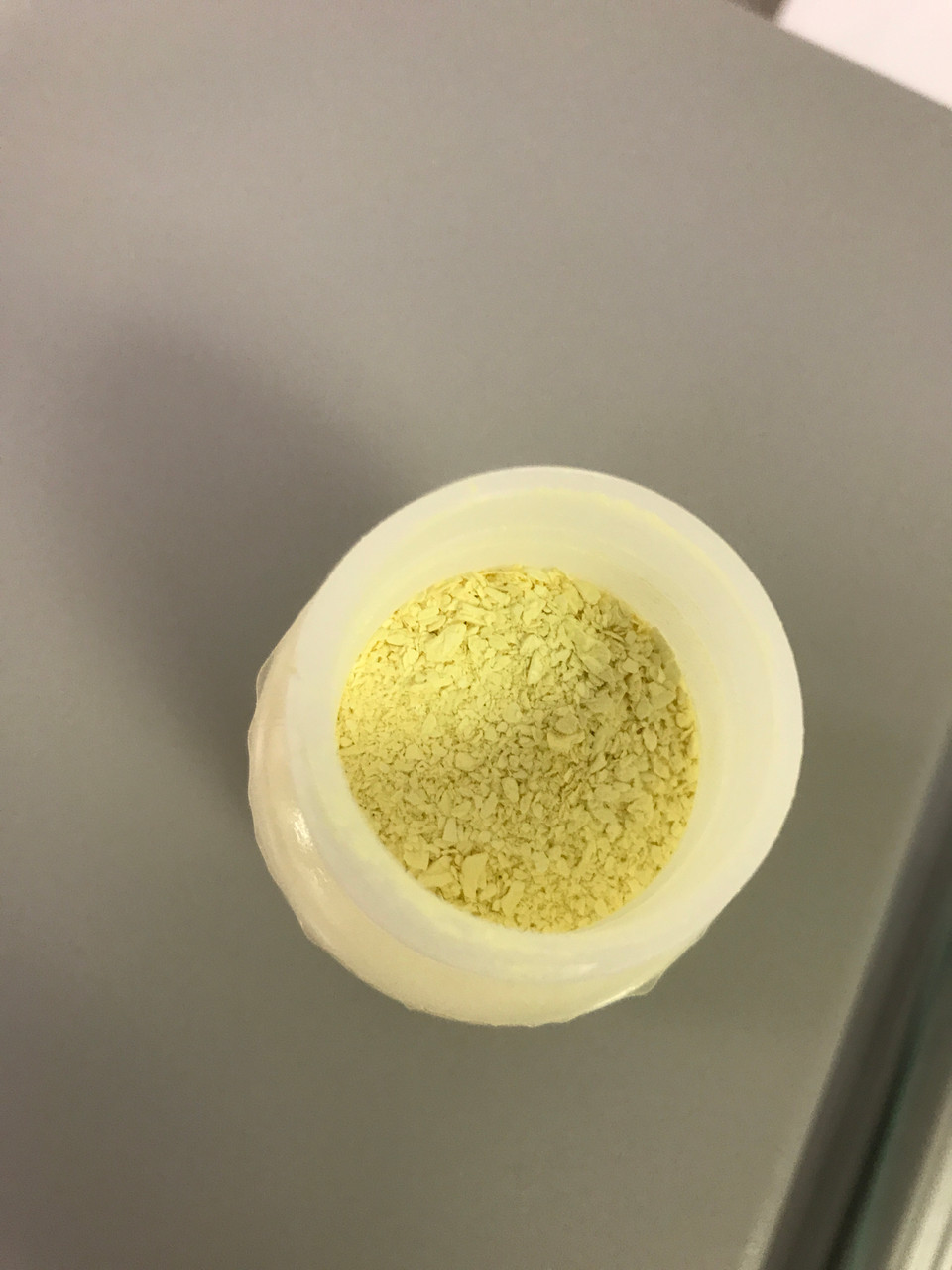

High temperature polyimide [already fully imidized, no further curing/imidization required] soluble in many organic solvents. Tg 326 C, 20 g package

5218 Resin, A Soluble Polymide

Typical Solvents:

Methylene chloride, Ethylene chloride, Chloroform, Tetrachloroethane, Tetrahydrofurane (THF), Dioxane, Acetophenone, Cyclohexanone, m-Cresol, g-Butyrolactone, Dimethylformamide (DMF), Dimethylacetamide (DMAC), N-methylpyrrolidone (NMP)

ONLY FOR USA CUSTOMERS